Belts

Among the production machines in a bindery, a conveying system is the base: flat transport, uphill transport, vertical transport, suspended transport. And devices to allow the free passage of operators and semi-finished products across (e.g. by forklift) are needed too. Variable-length conveyors, curves with different radius and accessories such as guides and rollers are Solema components that, combined, can solve every production requirement by adapting to the available spaces.

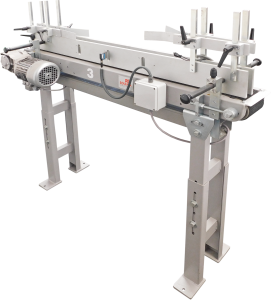

LINEAR BELT CONVEYORS

The Solema belt conveyors are designed with a modular system and can be built with any length between 500 and 7500 millimetres. Depending on application, different type of optional are available like: side guides, accelerating rollers, turning pivot, de-stacking devices, ecc.. The conveyors are available in standard width of 150, 200, 400, 500 mm, but every intermediate size is possible on request.

TELESCOPIC BELT CONVEYORS

For application where the length of the conveyor must change according to the size of the book or to the configuration of the line, Solema can supply belt conveyors with a telescopic end. The stroke of the telescoping part can vary depending on request between 250 and 850 mm.

VERTICAL BELT CONVEYORS

A range of conveyor with continuous side guides is available to transport the products in vertical position.

BUMP TURN

To change the product orientation, we have different type of 90° bump turn available for different sizes and applications.

WALK THROUGHS

To improve the operative configuration of the lines and create walk ways between the different machines to the operator.

DELTA CONVEYORS

Delta conveyors find their ideal application on lines for unloading of the sewing machines and more in general on aerial lines, for their flexibility and sturdiness thanks to the aluminium profile that makes their structure.

GRAVITY CONVEYOR

Any configuration can be created with these idle rollers conveyors, in order to optimize the product flow in the available space.